Choosing the suitable microcontroller is a crucial choice that may make all the difference in the success of your robotics project, especially in the fast-paced field where innovation is boundless. Whatever level of experience you have with robotics—from beginners to experts—the microcontroller you select will act as the digital brain of your project, dictating its capabilities and limiting the scope of your creative options. The purpose of this article is to demystify the complexities involved in choosing a microcontroller by walking you through the important elements to take into account and offering advice to help you make an informed decision that fits the specific needs and goals of your project. The first step in realizing your robotic vision is to grasp the subtleties of microcontroller possibilities, whether you’re building basic line-following robots or complex AI-driven devices.

What is Microcontroller

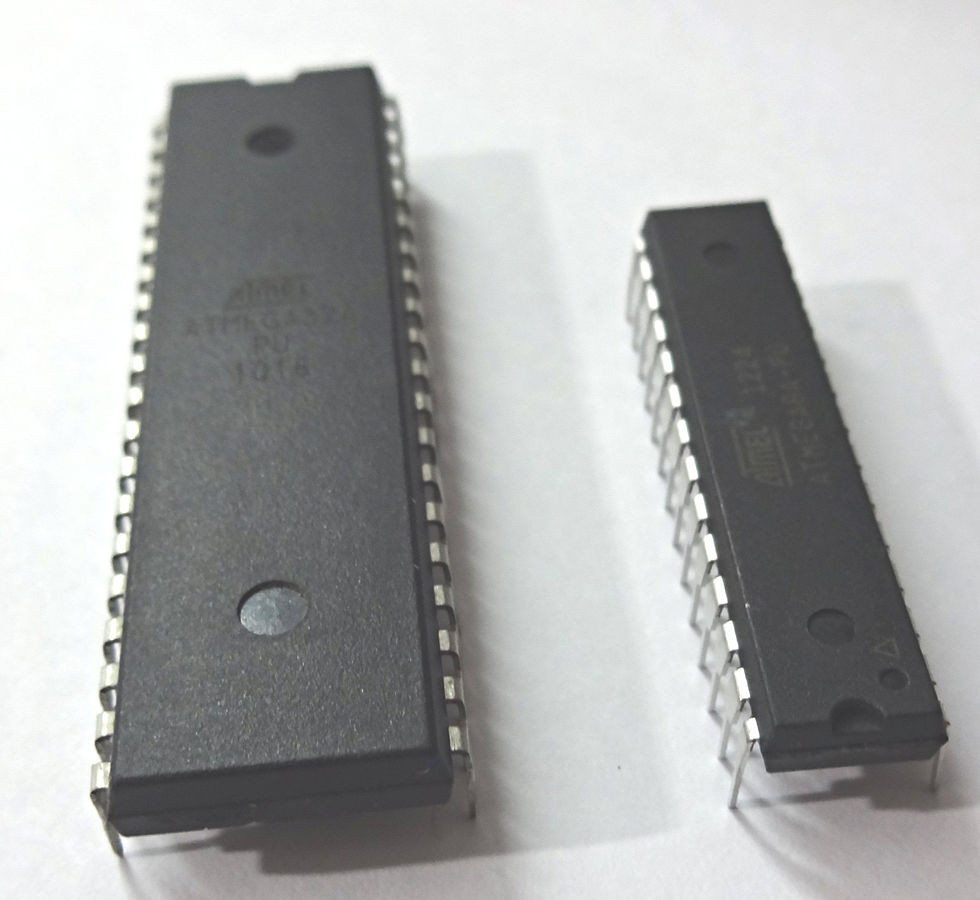

A microcontroller is a tiny integrated circuit (IC) computer that is used to manage electrical systems and carry out particular functions. Comprising a central processing unit (CPU), memory, input/output (I/O) ports, and many peripherals, it is essentially a small and independent system.

Processing Power

One of the most important things to take into account when choosing a microcontroller for your robotics project is its processing capability. Selecting a microcontroller with enough computing power to power your robot’s motors, sensors, and other parts is important.

Memory

Another crucial component to take into account when choosing a microcontroller is memory. To save the programming code for your robot and any data that its sensors may gather, you will need adequate memory.

Power Consumption

When building a robot, power consumption must be considered as it might impact the robot’s total runtime and battery life. To maximize the battery life of your robot, use a microprocessor with minimal power consumption.

Connectivity

The functioning of your robot may depend on connectivity features like Wi-Fi, Bluetooth, or USB, depending on how it will be used. A microcontroller that supports the connectivity choices required for your project is what you should be looking for.

Price

And last, the microcontroller’s cost is an important consideration. Selecting a microcontroller that meets your needs and budget while providing the features and functionalities required for your robotics project is important.

Is there any Best Microcontroller for Robotics?

The selection of a microcontroller for robotics is contingent upon many factors, including the particular demands of your project, your level of expertise and knowledge with multiple platforms, and the resources at your disposal. As such, there is no one “best” microcontroller for robotics.

Popular Choices of Microcontrollers for Robotics

Arduino

Robotics uses Arduino boards, including the Uno and Mega, extensively because of their ease of use and beginner-friendliness. Their broad community and abundance of libraries facilitate resource discovery and speedy startup.

Raspberry Pi

The Raspberry Pi, albeit not a microcontroller in the conventional sense, is a well-liked option for robotics projects requiring additional processing power. Like the Raspberry Pi 4, Raspberry Pi devices include a whole computer on a single board and are capable of handling sophisticated tasks like machine learning and image processing.

STM32

STMicroelectronics’ STM32 microcontrollers are renowned for their functionality and abundance of choices. They are built on the ARM Cortex-M cores and are available in many varieties with varying features and functionalities to accommodate a range of robotics applications.

ESP32

Because of its popular built-in Bluetooth and Wi-Fi capabilities, the ESP32 microcontroller is a good choice for robotics applications that need wireless communication. It provides a nice mix of functionality and price and is built on the Xtensa LX6 core.

PIC

Robotics has long made extensive use of Microchip Technology’s PIC microcontrollers. Programming and debugging are greatly supported by the MPLAB development environment, and they give a variety of alternatives with varying performance levels.

Keep in mind that there are other additional microcontrollers out there that can be appropriate for robotics projects; this is by no means a complete list. Before choosing, it’s crucial to assess your unique needs and take into account elements like processor speed, I/O capacity, community support, and your level of platform experience.

Application of Microcontroller in Robotics

Motor Control

Robotic systems frequently employ microcontrollers to regulate their motors. Robots can execute exact motions and manipulations because of their ability to create accurate control signals that may be used to drive DC motors, stepper motors, or servo motors.

Sensor Integration

Robotic systems may incorporate several sensors thanks to microcontrollers. By reading information from sensors like accelerometers, gyroscopes, proximity sensors, and cameras, they enable robots to see and communicate with their surroundings.

Autonomous Navigation

Robots that navigate autonomously rely heavily on microcontrollers. To enable autonomous mobility and path planning, they may interpret sensor data, apply mapping and localization algorithms, and make judgments depending on the input.

Human-Machine Interaction

Microcontrollers are utilized to offer outputs for human-machine interaction and to communicate with user input devices. They can handle inputs from buttons, switches, touchscreens, or speech recognition systems, and operate actuators like displays, speakers, or haptic feedback devices.

Communication and Networking

Microcontrollers facilitate communication between robots and external equipment or networks. They may handle protocols such as Wi-Fi, Bluetooth, Ethernet, or bus, allowing robots to exchange data, receive orders, or connect to the Internet of Things (IoT) ecosystem.

Real-Time Control

Microcontrollers are well-suited for real-time control tasks in robotics. They can instantly respond to sensor inputs, perform control algorithms, and alter robot behavior in real time, assuring stability and safety in dynamic conditions.

Data Processing and Decision Making

Microcontrollers are utilized for data processing and decision-making activities in robotics. They can interpret sensor data, do computations, and run algorithms for tasks like image processing, object identification, machine learning, or path planning.

Power Management

Microcontrollers can efficiently manage power in robotic systems. They may manage power distribution, optimize energy utilization, and adopt power-saving methods to increase battery life and enhance overall efficiency.

Conclusion

In conclusion, choosing the ideal microcontroller for robotics projects depends on several criteria. There is no one-size-fits-all option, as the ideal choice will vary depending on the precise needs of your robotic application. By analyzing your project’s demands, examining the capabilities and advantages of different microcontrollers, and reading example projects and tutorials, you may pick the microcontroller that best corresponds with your robotics ambitions. With the correct microcontroller at the foundation of your robotic system, you may unleash a world of possibilities and bring your revolutionary robotics ideas to life.